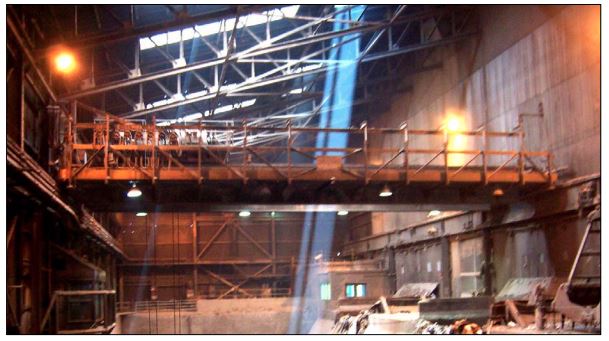

When it comes to selecting the right motor for your overhead crane, there are several factors that need to be considered. From power requirements to torque calculations, each detail plays a crucial role in ensuring the smooth and efficient operation of your crane. In this comprehensive guide, we will delve into the process of motor selection for overhead cranes, providing you with all the necessary information to make an informed decision. So, let’s get started!

Analyzing the Cyclic Duration Factor

1. Understanding the Power Requirements

The first step in selecting a motor for your overhead crane is to determine the power requirements. This includes considering the thermal power, maximum rated torque, and maximum acceleration torque. By understanding these requirements, you can ensure that the motor you choose is capable of handling the load and operating conditions of your crane.

2. Analyzing the Cyclic Duration Factor

Next, it’s important to consider the cyclic duration factor (CDF) of the motor. The CDF is a measure of the duty cycle of the motor and provides valuable information about its intermittent periodic duty. By analyzing the CDF, you can determine the appropriate motor for your crane based on its operational patterns and duration.

3. Evaluating the Number of Cycles per Hour

The number of cycles per hour is another critical factor to consider when selecting a motor for your overhead crane. This parameter determines the frequency at which the motor will be operating and helps in determining its durability and efficiency. It is important to choose a motor that can withstand the expected number of cycles per hour without compromising its performance.

4. Choosing the Right Type of Control

The type of control for your overhead crane motor is an essential consideration. This includes determining the type of braking system and speed regulation required for your crane. Depending on your specific needs, you may opt for contactor-based control, eddy current systems, or variable frequency drives (VFD) to ensure precise control over the motor’s speed and braking.

5. Selecting the Appropriate Power Feed

The power feed for your crane motor is another crucial aspect to consider. Whether it is a direct power supply or through an inverter drive, selecting the right power feed ensures efficient operation and minimizes energy consumption. Additionally, the type of power feed can also impact the motor’s speed control and overall performance.

6. Considering the Degree of Protection

The degree of protection for your motor is vital, especially in environments with varying conditions. Factors such as dust, moisture, and temperature fluctuations can impact the motor’s performance and lifespan. Therefore, it is essential to choose a motor with the appropriate degree of protection to ensure its longevity and optimal operation.

7. Factoring in Ambient Temperature and Altitude

The ambient temperature and altitude of the operating environment can significantly affect the motor’s performance. High temperatures or extreme altitudes can lead to decreased motor efficiency and potential overheating issues. It is crucial to consider these factors and choose a motor that can withstand the specific environmental conditions of your crane’s location.

8. Thermal Calculation for Motor Dimensioning

To ensure the motor’s reliability and longevity, a thermal calculation is required for dimensioning. This calculation, based on industry standards, helps determine the motor’s thermal limits and ensures it can handle the expected load and operating conditions without overheating. It is essential to perform this calculation to select a motor that meets the required thermal criteria.

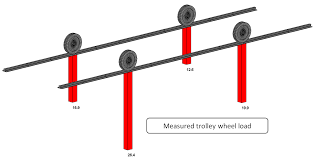

9. Determining the Maximum Torque

The maximum torque is a critical factor in selecting a motor for your overhead crane. This includes considering the torque requirements for hoisting mechanisms and horizontal motions. By understanding the maximum torque needed for your crane’s specific operations, you can choose a motor that can provide the necessary power and torque output.

10. Additional Considerations and Criteria

While the above factors cover the primary considerations for motor selection in overhead cranes, there may be additional criteria based on the driving system or specific requirements of your crane. It is essential to thoroughly evaluate all relevant factors and consult with industry professionals to ensure you make the best motor selection for your overhead crane.

With a comprehensive understanding of the power requirements, duty cycle, control type, power feed, degree of protection, and other critical factors, you can confidently select the perfect motor for your overhead crane. Remember to perform the necessary calculations, consider the environmental conditions, and choose a reliable motor that meets your crane’s specific needs. By doing so, you can ensure the smooth and efficient operation of your overhead crane for years to come.