## Introduction

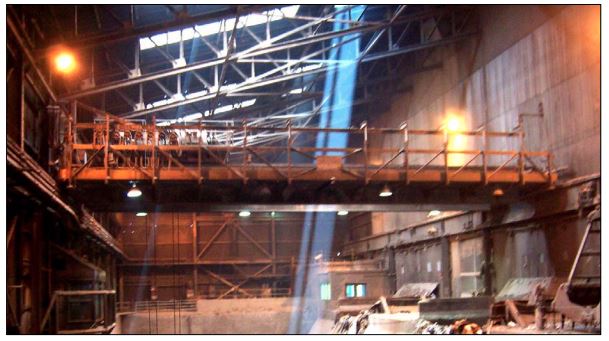

Boom and jib cranes are essential equipment in various industries, allowing for efficient lifting and positioning of heavy loads. However, determining the maximum load capacity of these cranes is crucial to ensure safe and effective operations. In this article, we will explore the process of calculating the load capacity of boom and jib cranes, taking into account factors such as configuration, deflection, and manufacturer guidelines.

Calculating the Maximum Load Capacity of Boom and Jib Cranes

Understanding Crane Load Capacity

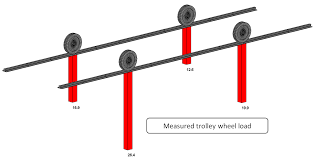

A crane’s load capacity is not a static value but rather depends on its specific configuration. Manufacturers provide loading charts for each crane type, specifying the maximum gross load for different boom lengths, angles, and load radii. These charts serve as a guide for calculating the maximum net load that a crane can safely handle. It is important to note that the mass of the load and the loading stress on the crane are two distinct factors that should not be confused.

Reading a Crane’s Loading Capacity from a Load Rating Chart

To determine a crane’s maximum loading capacity, it is essential to consult the manufacturer’s load rating chart. This chart provides a comprehensive overview of the crane’s capabilities based on boom length, angle, and load radius. Let’s take a closer look at an example load rating chart for the Grove RT650E crane:

| Boom Length (ft) | Lift Radius (ft) | Maximum Gross Load (lbs) |

|---|---|---|

| 33 | 10 | 100,000 |

| 33 | 15 | 80,000 |

| 60 | 10 | 70,000 |

| 60 | 15 | 50,000 |

In this example, the chart provides the maximum gross load capacity in pounds for different boom lengths and lift radii. For instance, when the boom extends 33 feet at an angle of 69.5 degrees to the horizontal, the crane can handle a maximum gross load of 100,000 pounds at a lift radius of 10 feet. It is important to note that the maximum gross load indicates the combined mass of the lifted object and all the crane’s lifting accessories.

Factors Affecting Crane Load Capacity

Several factors can significantly impact a crane’s load capacity, including its base configuration, wind conditions, boom angle, and pick-up point relative to the crane’s center of gravity. For example, if a crane is operating in its front quadrant and strong winds blow from behind, the boom can deflect forward, reducing the boom angle, increasing the load radius, and decreasing the safe load capacity. Operators must consider these factors to ensure safe lifting operations.

Calculating a Crane’s Maximum Net Load Capacity

The maximum net load capacity of a crane is determined by deducting the mass of all lifting accessories from the maximum gross load specified in the load rating chart. This includes the mass of blocks, balls, wire rope reeving, as well as any excess hanging wire rope and unnecessary jibs. Let’s take a closer look at how to calculate the maximum net load capacity:

- Determine the total mass of all lifting accessories, including the block and hook.

- Calculate the total mass of the wire rope used in lifting from the boom tip to the ground.

- Subtract the total mass of lifting accessories and wire rope from the maximum gross load specified in the load rating chart.

For example, if the maximum gross load capacity for a particular crane configuration is 60,000 pounds, and the total mass of lifting accessories and wire rope is 5,350 pounds, the maximum net load capacity would be 53,800 pounds. It is important to note that the crane’s net load is the mass of the object being lifted and offloaded during its operations.

Considering Deflection in Load Calculations

Deflection is a common phenomenon in crane operations, referring to the bending or flexing of the boom or jib when lifting a load. All crane booms and jibs have inherent flexibility to absorb the pulling force exerted by the lifting weight. However, it is crucial to consider deflection when performing load calculations to ensure safe operations.

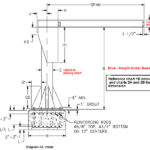

To account for deflection, manufacturers provide guidelines specifying the maximum allowable deflection factor. By dividing the length of the jib span by the manufacturer-specified deflection factor, it is possible to calculate the maximum permitted deflection in inches. It is important to consult the manufacturer’s guidelines for the specific crane type and model to ensure accurate calculations.

Measuring Deflection in Jib Cranes

While deflection limits for boom cranes are well-documented, there are no published deflection limits for jib cranes. Therefore, it is necessary to rely on the manufacturer’s instructions to determine the deflection guidelines for each crane design. These guidelines will enable operators to calculate the maximum allowable deflection, ensuring optimal crane usage and safety.

Typically, deflection limits for jib cranes vary depending on the crane type and installation. For example, free-standing jib cranes and mast jib cranes typically have a deflection limit of R/150, while articulated jib cranes may have a deflection limit of R/200. Workstation cantilever cranes often have a deflection limit of L/225. It is crucial to refer to the manufacturer’s guidelines to determine the appropriate deflection limit for a specific jib crane.

Safety Considerations When Using Jib Cranes

Safety is paramount when operating jib cranes, and considering deflection is crucial to minimize safety risks. As deflection increases during a hoist, the safety risk also increases. Therefore, it is essential to follow safety guidelines and regulations to ensure the well-being of operators and the integrity of the lifting operation.

Before hoisting, operators should consult the crane manufacturer’s instructions to determine load capacity and deflection limitations. During the hoisting process, operators must remain vigilant and be aware of their surroundings. Increasing the radius while lifting the load can compensate for deflection and swinging. After hoisting, it is advisable to lower the jib slowly to reduce deflection before setting the load on the ground.

Selecting the Right Jib Crane

When selecting a jib crane, several factors should be considered to ensure it meets the specific requirements of the intended application. These factors include budget, installation cost, available structural support, powered operation needs, and the matching of features and design to the intended use. It is crucial to evaluate these factors to choose the most suitable jib crane for the desired tasks.

Conclusion

Calculating the maximum load capacity of boom and jib cranes is an essential step in ensuring safe and efficient lifting operations. By referring to the manufacturer’s load rating chart, considering deflection, and following safety guidelines, operators can determine the maximum net load capacity and make informed decisions during lifting operations. It is crucial to prioritize safety and select the right crane for the specific application to achieve optimal results.