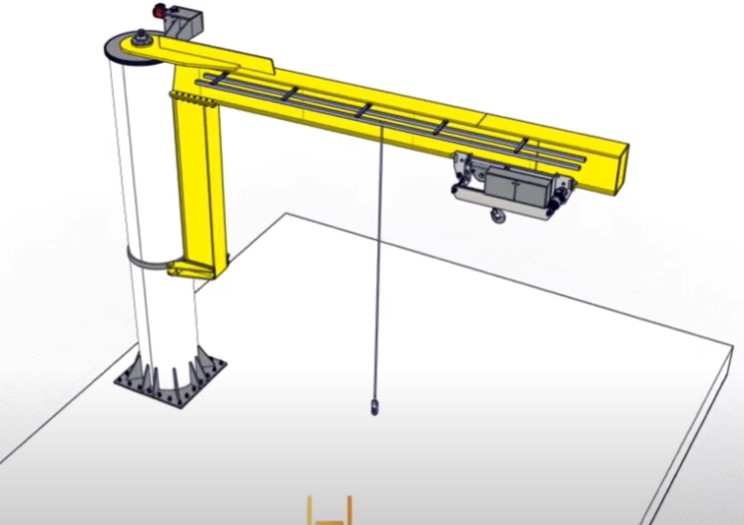

Jib cranes, essential tools in various industries for lifting and transporting heavy loads, consist of a horizontal beam, known as the jib, supported by a vertical mast. However, crane deflection, a critical factor in the design and operation of jib cranes, needs to be considered. Deflection, in the definition of deflection in engineering, refers to the relative displacement or bending of the crane’s components under load. In this comprehensive guide, we will delve into the deflection meaning in engineering, its importance, and how it can be calculated in the context of jib cranes.

Deflection: A Key Consideration in Jib Crane Design

The crane deflection of a jib crane plays a vital role in its overall performance, safety, and efficiency. When a crane is subjected to a load, its components, such as the jib arm and mast column, may experience deflection due to the applied forces. Excessive crane boom deflection can lead to a range of issues, including structural instability, reduced load capacity, and increased risk of fatigue failure. Therefore, understanding and controlling allowable deflection limits is crucial to ensure the safe and optimal functioning of jib cranes.

Measuring Deflection in Jib Cranes

To accurately measure deflection in jib cranes, or to understand how to measure deflection, manufacturers typically specify a maximum allowable deflection ratio based on the crane’s type and applicable standards. The most commonly used method for measuring deflection is the L/150 rule, where L represents the beam length of the crane member that is deflecting. This deflection limit formula allows for consistent measurement across different units of measurement.

For instance, if you have a jib crane with an 8-foot (2.4-meter) boom and the manufacturer allows L/150 deflection, the maximum crane deflection at 100% of the crane’s rated capacity should be approximately 0.64 inches (16 mm). This maximum deflection calculation ensures that the crane remains within safe operating limits and minimizes the risk of structural failure.

Importance of Deflection in Jib Crane Selection

Crane deflection is a critical factor to consider when selecting a jib crane, or an articulating jib, for a specific application. It can directly impact both the ergonomic aspects and the safety of crane operation. Higher deflection in a jib crane makes it more challenging to handle loads, leading to increased operator fatigue. Additionally, excessive deflection can cause the load to shift unexpectedly, posing a risk of collision or injury. Therefore, it is essential to choose a jib crane with a deflection limit that aligns with the intended usage and load requirements.

Understanding Organizational Specifications for Deflection

It is important to note that there is no published national standard for allowable deflection limits in jib cranes or overhead cranes. Instead, manufacturers have the flexibility to design cranes based on their own risk tolerance and engineering expertise. This means that different manufacturers may have varying crane deflection guidelines for seemingly similar jib cranes. It is crucial for end-users, purchasers, and crane dealers to thoroughly evaluate and compare capacity and deflection specifications when selecting a jib crane.

Vertical Deflection Criteria in Jib Cranes

Vertical deflection criteria, or the vertical deflection formula, refer to the maximum allowable vertical deflection ratio in a jib crane. While crane deflection may vary depending on the crane’s design and intended usage, most manufacturers adhere to an approximate deflection limit of L/150. This means that the vertical deflection should be within the specified limit when the crane is operating at 100% of its rated capacity. By following these guidelines, manufacturers ensure the safety and reliability of their jib cranes.

Horizontal Deflection Criteria in Jib Cranes

Similar to vertical deflection, horizontal deflection criteria play a crucial role in the safe and efficient operation of jib cranes. Horizontal deflection, or horizontal displacement, refers to the displacement of the crane’s runway beam at the centerline when subjected to a full-rated load. Manufacturers typically follow a deflection limit of L/400 for crane deflection in bridge cranes and jib cranes. This ensures that the crane remains stable and maintains its structural integrity during operation.

Calculating Deflection in Jib Cranes

To calculate deflection in jib cranes, or to apply the deflection equation, various formulas and equations can be used based on the type of crane and its specific design. The crane deflection calculation involves considering factors such as the length of the crane member, the applied load, and the material properties of the crane components. By applying these formulas and considering the manufacturer’s specified deflection limits, engineers can accurately assess and control deflection in jib cranes through stress analysis.

Factors Affecting Deflection in Jib Cranes

Several factors can influence the crane deflection of jib cranes. These include the weight of the load being lifted, the distribution of the load on the crane’s structure, the design of the crane, and the maintenance and condition of the crane components. It is crucial to consider these factors during the design, installation, and operation of jib cranes, including overhead cranes, to ensure safe and efficient performance.

Importance of Compliance with Deflection Standards

Compliance with crane deflection standards, such as ASME B30.2, is essential for ensuring the safe and reliable operation of overhead jib cranes. Manufacturers must adhere to these industry-specific standards and guidelines to ensure that their cranes meet the required deflection limits. Likewise, end-users and purchasers should prioritize working with reputable manufacturers who adhere to these standards to guarantee the performance and longevity of their overhead jib cranes.

Conclusion

Crane deflection is a critical factor to consider in the design, selection, and operation of overhead jib cranes. By understanding and controlling deflection, manufacturers can ensure the safety, efficiency, and reliability of their cranes. For end-users and purchasers, it is essential to evaluate and compare deflection limit specifications when selecting a jib crane. By adhering to industry standards and guidelines, the risks associated with excessive deflection can be minimized, resulting in safe and optimal crane operation.